When choosing an explosion-proof lighting fixture for a specific hazardous location, we need to check its certification to see which zone area this ex-lighting fixture can be used in. For example, if your workplace is a Zone 2 hazardous area, you should choose lights that at least meet Zone 2 standards or higher standards, such as Zone 1 or Zone 0.

P.S.: Read this post if you have yet to understand zone classification(ATEX rating for working areas)

However, understanding types of protection for Ex lighting can help you identify zones the lights will be suitable for.

Typically, there are 9 types of protection for explosion-proof equipment, but Ex e and Ex d are often adopted in the design of explosion-proof lighting fixtures.

Brief Introduction of Ex d and Ex e

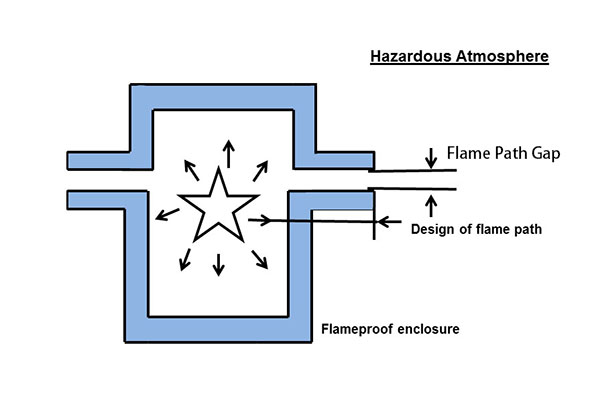

Ex d (flameproof enclosure) – lighting fixtures with Ex d protection should contain the explosion within their enclosure, and its enclosure must be thick enough to withstand the air pressure the explosion will generate, so even if there is an explosion inside the lighting fixtures, the Ex d enclosure will not transmit the explosion outside. The enclosure also has a series of flame paths against flame transmission so as to control the surface temperature under a required value.

Ex e (increased safety) – lighting fixtures with Ex e protection require higher ex-proof standards for the components inside the enclosure, Ex e try to prevent ignition resource, arcs, sparks, or high temperatures occur inside the enclosure by using components with appropriate ex-proof standard and designing larger gaps between components to control temperature and other ignition resources.

Differences Between Ex d And Ex e

Let’s explore the difference between Ex d and Ex e and how it impacts our decision-making process in 5 distinct aspects.

#1 Size and Weight

Ex d lighting fixtures pay a lot of effort into the enclosure, which must withstand the pressure caused by an explosion inside the enclosure, and must have a large flame path to snuff the fire out, so it is always bigger and heavier than the ones with Ex e standards.

#2 Maintenance

Regular maintenance can preclude function failure of these lights, especially the explosion-proof function.

Ex d lighting fixtures require flame-path around the flange. The flame paths are designed to extinguish flames if an explosion happens within the light housing.

The size of the flame path gap is critical. In order to keep certain dimensions, we usually design several bolts to fasten the enclosure with s specific torque. So if you want to maintain an ex-d enclosure, you have to unscrew several bolts first.

In addition, reassembling the enclosure after maintenance is a painstaking task. It requires careful attention to ensure that the flame path gap is restored properly. Failing to do so will render the flameproofing feature invalid.

Furthermore, you have to be very careful when maintaining Ex d flameproof enclosure, because even a small scratch, like one caused by a screwdriver, can make the flame path invalid, you can refer to the following video as Ex d enclosure testing.

The maintenance of Ex e is comparatively easy. Ex e do not have flamepaths, and do not have so many bolts to unscrew and reassemble.

And the Ex d luminaires’ large size and weight can be another challenge during maintenance.

#3 Installation

Under different standards, Exd luminaires tend to have thicker housing to withstand the blast and resultant explosion pressure, so they are more big and heavy to handle in installation.

Exe luminaries only have strict requirements for the components and do not have so many requirements for the enclosure, so they are always lighter and easier to install and maintain.

#4 Temperature Ratings & Gas Groups

Gas and vapor will change the physical status at low temperatures, so they may block the flame paths of Exd lights, while Exe lights do not have this kind of design, so Exe lights can be installed in locations below -15°C.

Gas Group I – Mines

Gas Group II – Surface above ground industries

Gas Sub Group A – Less easily ignited gases e.g., Ammonia, Methane, Ethane

Gas Sub Group B – Easily ignited gases e.g, Acrylic, Nitrile, Ethylene

Gas Sub Group C – Most easily ignited e.g., hydrogen or acetylene

If you want to find Exd equipment for a location classified with IIC gas groups, there will be few products to choose from, because IIC gas can be very easy to ignite so we need to use Exd equipment with even tighter flame gaps, this dramatically increases the manufacturing difficulties.

#5 Cost

Exe luminaires can be more expensive than Exd luminaires because Exe requires every component can meet explosion-proof standards, and Exd only requires the enclosure can meet ex-proof standards, so having so many components certificated with ATEX/IECEX can cost you much more money than only qualifying an enclosure.