Categories By Zones

Explosion Proof Lighting Manufacturer in China

Cressa designs and fabricates industrial explosion proof lighting for potentially explosive areas with flammable gasses and materials, such as offshore drilling, power plants, chemical warehouses, petrochemical facilities, wood sawmills, and so on.

Explosion-proof Accessories

Inquiry

More questions about our explosion proof lighting products?

Looking for lighting consultation, designs or quotations for your Ex lighting projects?

Leave your messages here, Let’s talk more.

Share your details below

Frequently Asked Questions

What Is Explosion Proof Lighting?

Explosion proof lighting is a type of special-purpose lighting that is designed to use in a situation with explosive atmospheres, where a mixture of oxygen and flammable substances, such as gases, vapors, dust, or powders exists at the same time, an explosion or fire disaster may occur immediately if any of ignition resources are added, such as an electrical spark, fire, and so on.

Common industrial lighting without appropriate shelter/protection measures for electronic components may generate sparks because of loose or damaged electrical connections, overloading electrical circuits, or short circuits.

Explosion-proof lightings belong to explosion proof equipment, according to the requirements of EN60079, there have more than 9 types of protection measures to prevent explosion proof equipment from explosive atmospheres so as to keep safety.

Code | Type of protection | Protection principle | CENELEC |

flameproof enclosure | Prevents transmission of the explosion outside | EN60079-1 | |

increased safety | Prevents high temperatures and sparks | EN60079-7 | |

Ex i | intrinsic safety | Low current/voltage supply | EN60079-11 |

Ex p | pressurized apparatus | Positive pressure device | EN60079-2 |

Ex m | moulding | encapsulated | EN60079-18 |

Ex o | oil immersion | Parts immersed in oil to isolate from explosive atmosphere | EN60079-6 |

Ex q | powder filling | Prevents transmission of explosion outside | EN60079-5 |

Ex n | protection “n” | As above, but for use in zone 2 | EN60079-15 |

Ex t | protection by enclosure | Dust explosion proof | EN60079-311 |

Take “Ex i” for example,

equipment/lighting with mark “Ex d” means their type of protection is “intrinsic safety”, the lights will be designed with low current/voltage supply to realize intrinsic safety.

Why Is Explosion Proof Lighting Necessary?

Areas that contain gases, vapor, or powders that are prone to explosion pose a risk when exposed to ignition sources such as electric arcs or sparks. To prevent such incidents, it is crucial to use explosion-proof lighting in these locations.

The locations includeoil fields, offshore oil/gas rig platforms, petrochemical facilities, and so on.

Inferno, or explosions can cause leaks of toxic liquid/gas in hazardous locations where these chemical substances are stored. Explosion proof lighting in this type of hazardous location is necessary to prevent fire and explosion from happening.

The locations includes chemical plants, warehouses, pharmaceutical factory, and so on.

12 Types Of Explosion Proof Light Fixtures

According to their uses, Explosion proof lights can be categorized into the following types

1. Explosion Proof Flood Lights: are designed to illuminate wide-area in hazardous locations, such as warehouses and factories. Floodlights usually have brackets, so you can mount them on walls or ceilings, small sized floodlights can also be installed in gas & oil rig platforms to provide visibility for the pathways. Ex floodlights are coated with special materials so as to prevent sparks from occurring when hit by other heavy objects. Since they are often used outdoors, IP65 ratings are required as a must.

2. Explosion Proof Platform Lights: are low wattages floodlight or low bay, they are specially designed for outdoor walkways and staircase illumination, so you can mount them on posts or railings to light areas where people are working or walking. ex platform lights are mostly used in outdoor areas of offshore oil gas rigs, chemical refineries, and power plants

3. Explosion Proof High Bay Lighting: is usually applied to locations with high ceilings, such as warehouses, and aircraft hangars. they are powerful with high-intensity lighting so as to provide clear visibility through long distances.

4. Explosion Proof LED Linear Lighting: is an upgraded type of high-bay. Linear lights not only can be used as high-bay in places with high ceilings but can also be mounted on walls, which offers flexibility to various applications.

According to different protection requirements, stainless steel grid shelters can be mounted in front of the lights, refer to the picture below.

5. Explosion Proof Fluorescent Lighting is traditional fluorescent lights with ATEX standards, they commonly come with grid shelter to protect the lights. Meanwhile, there is special protection around the electrical component so that the light has the ability to contain sparks in the lights.

6. Paint Booth Explosion Proof Lighting often indicates linear lights or ex-fluorescent lights that are used in the paint booths, where explosive hazardous vapors often fill the environment. This kind of ex-lighting should meet zone 0(IEC/CENELEC) or division 1(NEC/CEC) requirements

7. Explosion Proof Emergency Lights are lights that are intended to provide guidance for evacuation during emergencies, they usually come with batteries inside to illuminate escape routes for a limited amount of time. Emergency lights will light up automatically once there is a power outage.

Any explosion proof light fixture manufactured with built-in batteries can be applied in emergencies.

8. Explosion Proof Exit Signs are a type of Ex emergency lights, the exist signs work in both normal conditions and emergencies, with simple signs to show people the direction of evacuation. These exist signs are required to be visible in low-light conditions.

9. Explosion Proof Flashlights are a type of portable explosion proof lights, they are used for various tasks in hazardous locations, such as inspecting equipment, searching for leaks, and performing maintenance.

Flashlights adopt rechargeable batteries as energy sources, by using low voltage and low energy output, they can meet “Ex i” (EN60079-11) standards, so also called intrinsic safety flashlights.

10. Explosion Proof Work Light is a type of temporary lighting that is used on-spot for temporary tasks, besides explosion-proof standards, they also have to be strong enough to stand up to hit or fallen impact in harsh environments.

11. Explosion Proof Drop Light as known as explosion proof hand lamp, belongs to portable ex lighting, These kinds of lights are equipped with a hook at the top for hanging in workplaces, and long wires at the end for easy mobility. It operates on 220V AC input, so there is no need to worry about power shortage like with flashlights.

12. Portable Explosion Proof Lighting flashlights, work lights, and drop lights are all portable ex lighting, they offer flexible mobility to be taken to any workplace in explosive atmospheres that need illumination, so they are also called explosion proof temporary lighting.

Explosion Proof Lighting Classification

The hazardous locations where explosion proof lighting is applied are classified by standards of NEC(National Electrical Code), IEC(International Electrotechnical Commission), and ATEX(EU directives of safety standards for workplaces and equipment).

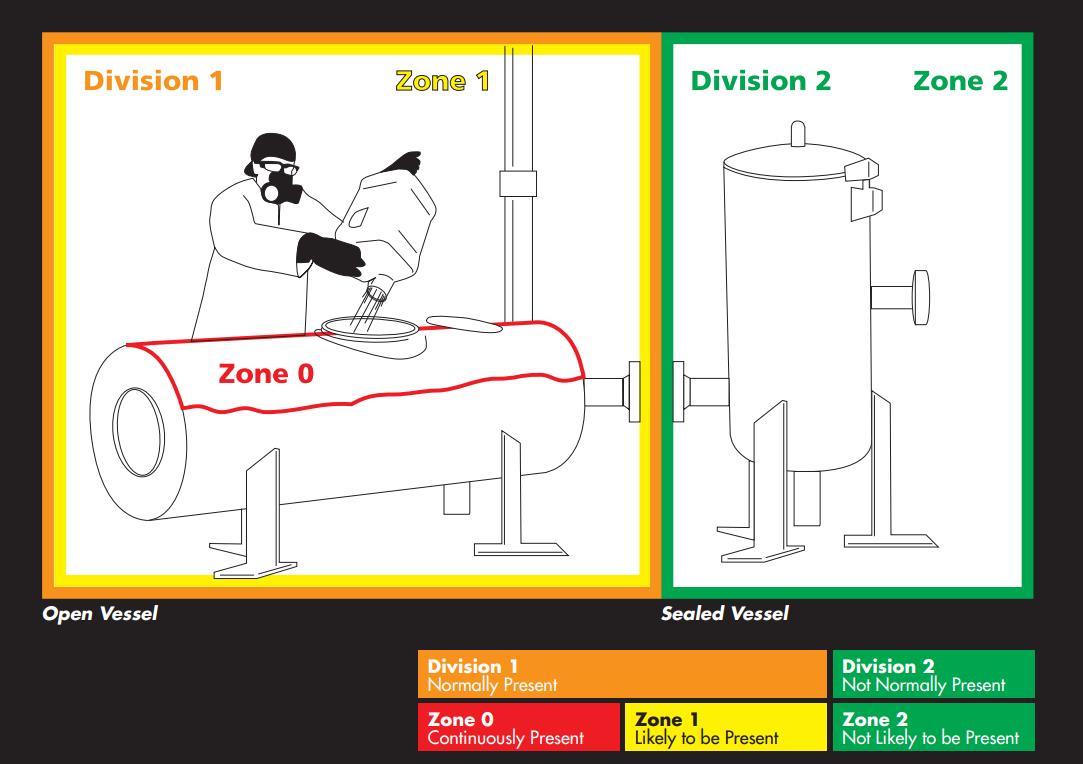

Division and Zone

NEC use “Division” to define hazardous locations, while IEC/ATEX divided hazardous locations into “Zone 0” “Zone 1”, and “Zone 2”

Refer to the following picture to understand the relationship between “Division” and “Zone”

Zone 0 indicates an area where explosive mixture is continuously present or present for long periods.

Zone 1 indicates an area in which explosive mixtures are likely to present in normal operation.

Zone 2 indicates an area where an explosive mixture is not likely to occur in normal operation. If it occurs, it will only exist for a short time.

Division 1 contains Zone 0 and Zone 1

Division 2 equals Zone 2

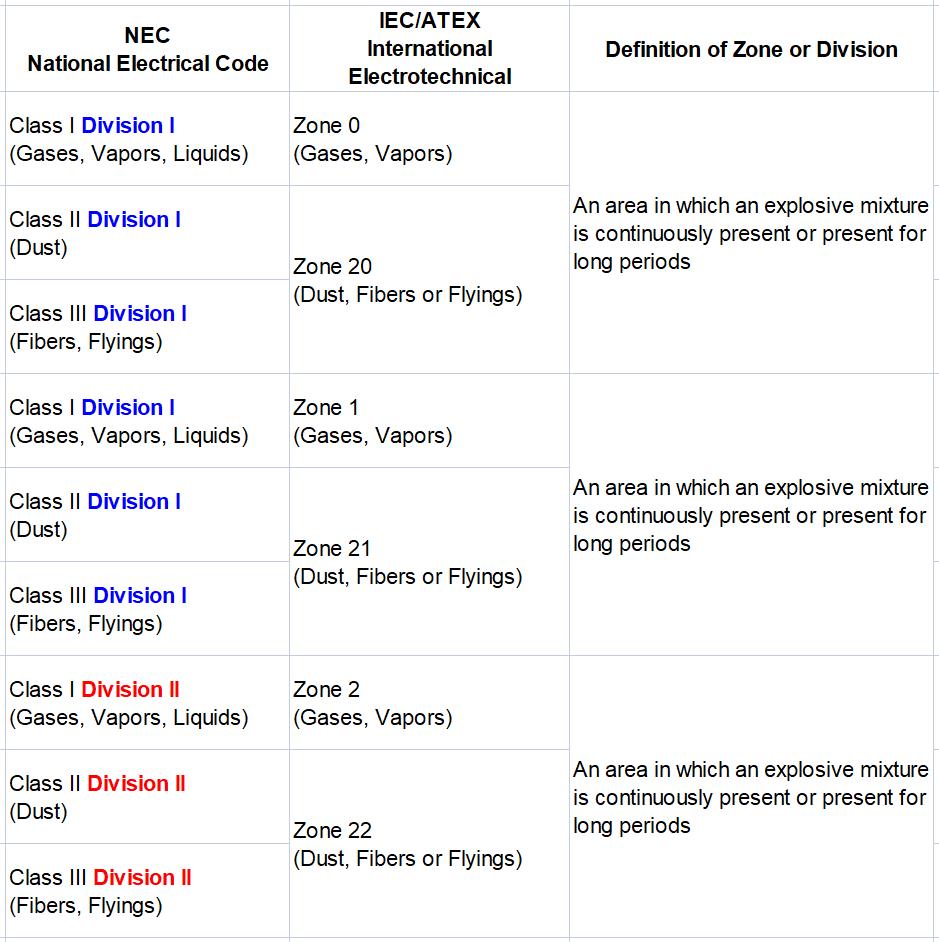

Class

Besides, NEC uses Class to identify substances(gases, vapors, liquids, dust, fibers, flyings) in explosive atmospheres

Class I = Gas, Vapors, Liquids

Class II = Dust

Class III = Fibers, Flyings

However, ATEX/IEC use zone 0, zone 1 and zone 2 for gas or vapors, zone 20, zone 21, zone 22 for dust, fibers or flyings.

Refer to the follow picture to see their relationship

ATEX is EU standards, and IECEX is international standards, refer to the following link to review more information about what’s the difference between them

Explosion Proof Lighting Standards

Understanding explosion proof lighting requirements, we should firstly learn standards of explosion proof lighting.

NFPA

The National Fire Protection Association (NFPA) is an international nonprofit organization in the United States. By publishing consensus codes and standards, NFPA is trying to eliminate loss caused by fires and electrical-related hazards globally.

NFPA497 (gases, vapors) and NFPA499 (dust) not only provide guidance on the classification of hazardous locations for electrical installations in chemical process areas but also provide guidance on the selection of electrical systems and equipment in hazardous locations.

Anyone (including electrical engineers, designers, installers, and maintainers of electrical equipment ) who need to handle electrical equipment in chemical process areas should learn NFPA 497 and NFPA 499.

NEC

The National Electrical Code (NEC) is under NFPA 70®, which belongs to the National Fire Codes series published by NFPA. NEC or NFPA 70 is standard for the safe installation of electrical systems and equipment in the U.S.

It covers wiring methods and electrical materials, electrical equipment, protection from electrical hazards, and procedures of installation and maintenance.

IEC

The International Electrotechnical Commission (IEC) is an international standards organization. IEC published international standards for electrical and electronic-related technologies, which cover fields from power generation, home appliances, office equipment, semiconductors, fiber optics, batteries, solar energy, nanotechnology, and marine energy.

MSHA

The Mine Safety and Health Administration (MSHA) is US based agency that publishes safety and health standards for mines. Its mission is to prevent accidents, injuries, and illnesses in the mining industry.

Mine lighting should get MSHA approved.

UL844

UL844 is a safety standard. Its name is “Luminaries for Use in Hazardous (Classified) Locations” UL844 includes requirements that light fixtures must use materials that are resistant to fire and explosion and light fixtures must be designed with protection to prevent ignition resources from flammable gases vapor, or dust.

ATEX

ATEX includes two EU directives(Directive 1999/92/EC and Directive 2014/34/EU) that defines safety standards for both equipment and workplaces in explosive atmospheres to prevent disasters caused by electrical systems and equipment from happening, such as fire, or explosion.

Read more about what is ATEX

IECEX

IECEX certification is released by IEC, IECEX is an international certificate for equipment that is planned to use in explosive atmospheres. Compared with ATEX, which is for the EU region, IECEX is recognized by many countries around the world.

Explosion Proof Light Fixture Applications

Oil & Gas

Offshore oil rigs are platforms built to explore petroleum and natural gas from the earth in deep oceans. The environment surrounding oil rig platforms is always filled with flammable gases and vapors, so lighting with explosion proof certificates ATEX or IECEX is a must for this kind of application.

Power Plants

Power plants, that adopt coal burning to generate electricity, may generate flammable gases by incomplete combustion of coal, ATEX zone 1 lighting (or D1C1 lighting) is needed in this kind of scenario.

Mines

Coal mines are always underground, explosion proof light fixtures for coal mines belong to equipment group I according to ATEX. coal mines is a comparable enclosed space underground. there may contain methane, carbon monoxide, or hydrogen sulfide gases. These gases are easy to ignite when meet electrical sparks from the LED lights without a protective shell and design.

Chemical Warehouses

Toxic liquids, volatile chemicals, flammable gases in condensence state, and valuable goods are stored in warehouses, in order to prevent fire disaster from happening, explosion proof light fixture is a good solution to chemical warehouses. With specially designed LED light housing, ignition resources like electrical sparks can be separated from the explosive atmospheres in chemical warehouses.

Refineries

Petroleum refineries and chemical refineries are those applications that are surrounded by volatile flammable gases and requires atex zone 2 lighting (D2C1 lighting)for the safety of human and factories.

Grain Processing Facilities

Grain processing factories will generate lots of small particulate floating in the air, so zone 20 atex lighting (D1C2 lighting) should be applied to the facilities.